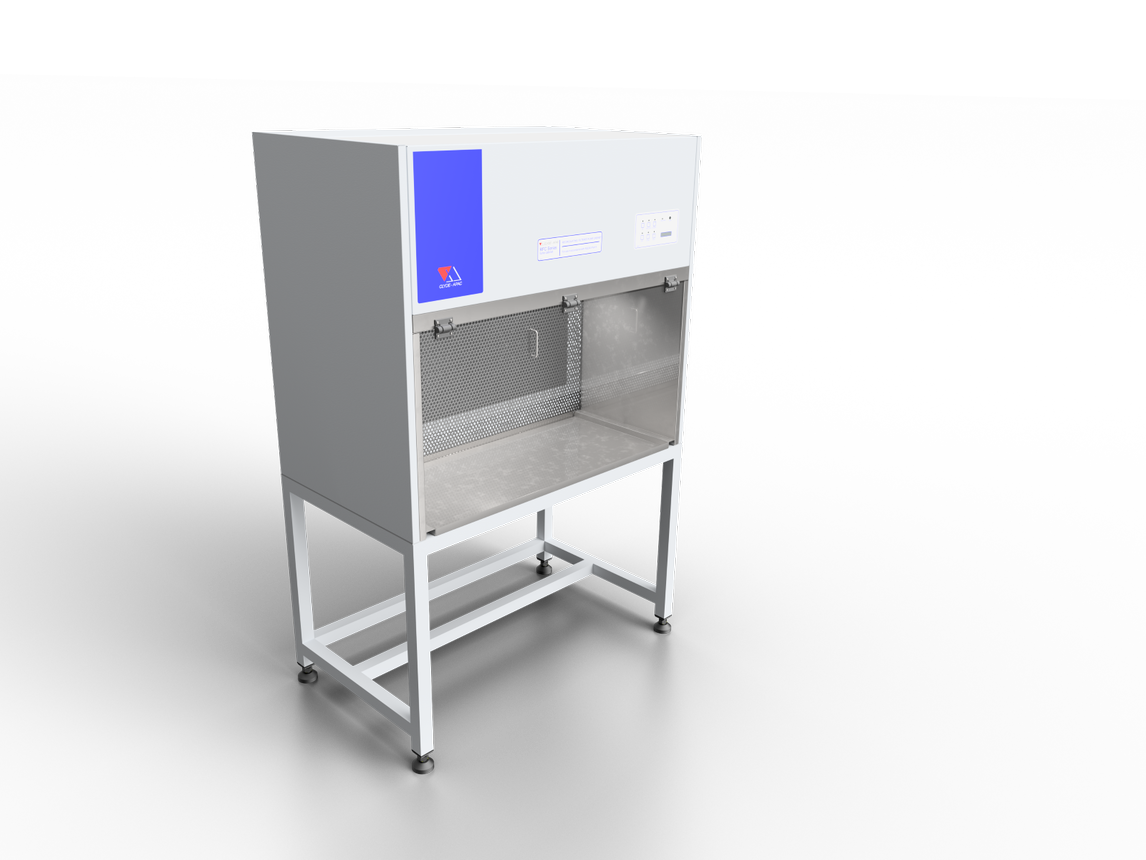

Recirculating Fume Cabinet RFC

Overview

These Recirculating Fume Cabinets are suitable for benchtop use and supplied with a stainless-steel work tray. When supplied without the work tray, the cabinet may be installed over a sink or an item of equipment. RFC cabinets can also be supplied with a special trolley or stand, allowing a separate trolley to be wheeled into the containment enclosure. The mobility of trolley-mounted RFC cabinets is a significant advantage in hospitals or large research institutions, where materials such as glutaraldehyde are handled at multiple locations. These applications include endoscope sterilisation.

The RFC cabinet has an inward air velocity maintained at > 0.5 m/s +/-20% for both benchtop and trolley-mounted installations. In most applications, filtered exhaust air may be discharged to the room. This avoids the air supply system problems that arise with ducted cabinets. In special cases, where the nature or concentration of the contaminant indicates, the cabinet exhaust may be connected to an exhaust fan/ duct system that discharges to atmosphere.

RFC cabinets are produced in two sizes, with 900 or 1200 mm nominal work zone width.

Filtration air exhausted from the top of the cabinet is filtered by a two-stage filtration system. A prefilter protects the final filter system from particulates > 5µm. The final activated carbon filter incorporates carbon granules with a selected chemical impregnation to optimise the arrestance of specific vapours. Specific impregnations are available for the handling of a wide range of contaminants, including formaldehyde and glutaraldehyde, Alkaline odours, Ammonia and amines, Inorganic acids and acidic odours, H2S and mercaptans and HCN.

Special adsorption filters are fitted for the capture of a wide range of vapours. Chemical impregnation of the carbon produces a chemical reaction similar to an oxidation process when the contaminant is adsorbed. This process extends filter life as the surface of the catalyst will not be covered by molecules trapped on it, thus enabling the process to be repeated. These filters will operate effectively in environments with temperatures up to 70oC and relative humidity up to 80%.

The cabinets outer casing is constructed from galvanized steel and powder-coated to AS2700 while the work zone is constructed in 304 stainless steel. A removable aluminium screen is fitted in front of the prefilter at the rear of the work zone. A variable speed controller regulates a direct drive motor/blower to enable the airflow to be maintained through filter life.

An easily-accessed, disposable polyester pre filter arrests not less than 90% of particulates > 5µm, thus prolonging carbon filter life. A warning light in the control panel signals the need for pre filter service.

Products supplied by Thermoline are factory-tested to ensure compliance and performance targets are met.

Additional testing and certification is recommended as follows:

- On-site prior to use

- After any electrical of mechanical maintenance

- After filter replacement

- After re-location

- At least annually

- In special circumstances, e.g. if faulty operation is suspected.

Technical Data

-

BrandAES Environmental

-

Models AvailableThree

-

Sizes900mm/1200mm/1700mm

-

Electrical2A/230V

-

Filter TypeCARBON

-

Complies WithAS 2243.9

Support

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- Where are the clean air cabinets supplied by Thermoline manufactured?

- All of the cabinets we supply are Australian Made by AES Environmental. AES has several manufacturing locations in Australia, and all of the Laminar Flow and High-Efficiency Filtration products are produced in their Minto, NSW facility.

- What is fume cupboard used for?

- Fume cupboards are used widely in laboratories and are designed to capture and remove airborne hazardous substances generated during laboratory experiments (e.g. gases, vapours, aerosols, biohazards and particulates/dust).

- Can Thermoline arrange installation and commissioning of my cabinet?

- Yes. Our suppliers have service divisions in most Australian states and territories and relies on qualified partners for other geographical locations. Each team is capable of providing on-site installation and NATA certification.

- What is a carbon filter used for in laboratory fume cabinets?

The primary function of a carbon filter in a laboratory fume cabinet is to adsorb and remove volatile organic compounds (VOCs) and other harmful chemicals that may be released into the air. Carbon filters typically contain activated carbon, a highly porous form of carbon with a large surface area. The large surface area of activated carbon allows it to adsorb a wide range of chemicals from the air, including VOCs, odours, and gases.

The carbon filter in a laboratory fume cabinet is usually located in the exhaust system, which removes chemicals from the air before it is exhausted to the outside environment. This helps to minimise the risk of exposure to hazardous chemicals for both the user and the environment.