High Temperature Lab Oven TOH-150F

This Australian Made high-temperature digital laboratory oven is suitable for applications where temperatures up to 300°C are required. The TOH oven is ideal for high baking, drying, conditioning and sterilising.

The convenient 150L oven features a PID controller and horizontal airflow pattern to ensure accurate temperature control and uniformity.

Overview

High temperature laboratory ovens are used in a wide range of scientific and industrial applications where elevated temperatures are required. They are designed to provide a controlled environment for heating and drying samples, conducting chemical reactions, and carrying out various other processes such as sterilising. The TOH-150F is used extensively in the aerospace industry.

Key Features

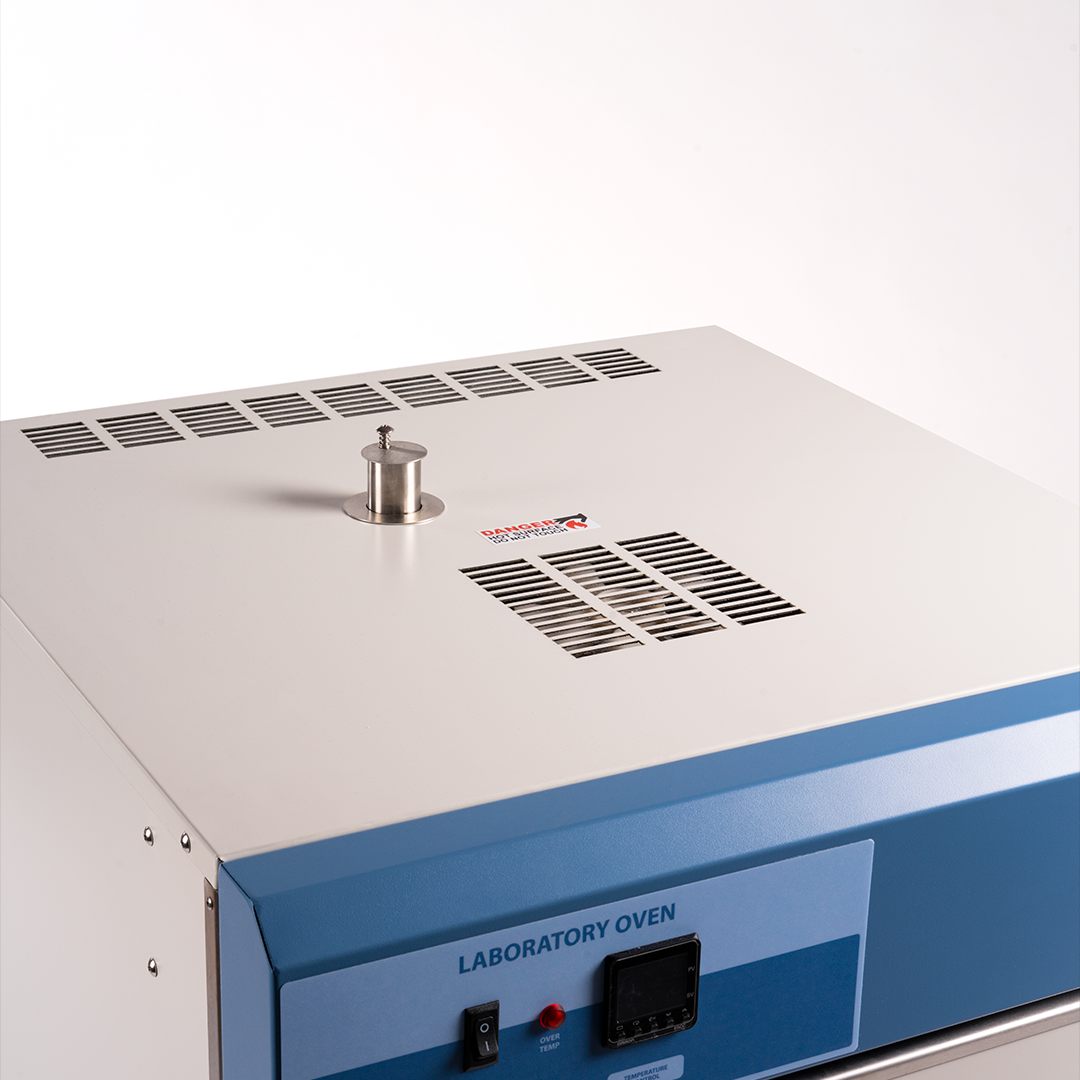

- Robust Construction: The Australian-made high temperature oven features a 316 stainless steel internal liner and stainless steel adjustable shelves.

- Efficient Airflow System: A fan forces air over a 3000-watt heating element and down the back wall through a perforated back panel. This ensures airflow over each shelf position, uniform temperature distribution throughout the workspace, and quick recovery after the oven has been opened.

- Advanced Temperature Control: The convenient 150L oven features a PID controller and horizontal airflow pattern to ensure accurate temperature control and uniformity.

Benefits

- High Performance: The TOH oven is ideal for high baking, drying, conditioning, and sterilising applications, reaching temperatures up to 300°C, making it suitable for demanding processes.

- Reliable and Durable: Built with a 316 stainless steel internal liner and stainless steel shelves, this oven ensures long-term durability and reliability, meeting the high standards expected from Australian-made products.

- Consistent and Uniform Heating: The advanced airflow system and PID controller provide precise temperature control and uniform heating, ensuring consistent results and efficient operation.

Summary

Thermoline's high temperature laboratory ovens offer the precision and reliability needed for various high-temperature applications. The TOH-150F model, with its robust construction, efficient airflow system, and advanced temperature control, is ideal for industries such as aerospace. These ovens are highly popular for their durability, performance, and the reliability expected from an Australian-made product.

Choose Thermoline high temperature laboratory ovens for your elevated temperature needs and experience the benefits of superior performance, consistent results, and reliable operation. Trust Thermoline to deliver the high-quality equipment essential for your critical scientific and industrial applications.

Specifications

- Dimensions

-

TOH-150F External WxDxH (mm) 630x660x1010 Internal WxDxH (mm) 500x510x600 Clearance Front (mm) 630 Back (mm) 100 Sides (mm) 100 - Technical Specifications

-

TOH-150F Temperature Range Ambient +10°C to 300°C Temperature Uniformity +/-4°C @ 200°C Heater Power 1500 watts Electrical 6.5A/230V Nominal Capacity 150L Porthole Diameter 13mm Weight 100kg - Features

-

TOH-150F Shelves (max @100mm spacing) 3 (max 4) Lockable Castors ✔ Rockwool High Temp Insulation ✔ Omron E5CC ✔ - Safety

-

TOH-150F Over Temperature Safety ✔ Over Current Protection ✔ - Options

-

TOH-150F BMS Plug No volt contact closure plug and socket connection to a Building Management System Additional Shelves Additional Stainless Steel shelves to suit Additional Shelves Key lockable door locks

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is the difference between a lab oven and a drying oven?

- A drying oven is design to remove moisture from the oven chamber by introducing dry air into the chamber. These ovens are typically designed to provide a consistent and low humidity environment, which is important for drying materials effectively. Drying ovens often feature a vent or exhaust system that allows moisture to be removed from the oven workspace. Generally speaking, a regular lab oven does not exhaust air so the moist air may continue to circulate inside the chamber.

- What is the process difference between a lab oven and a drying oven?

- A drying oven is designed to remove moisture from the oven chamber by introducing dry air. A lab oven's sole purpose is to designed to heat samples only. It works by recirculating the air around the chamber over a heating element that is controlled by a temperature controller.

- How do Laboratory Ovens Work?

- A laboratory oven works via the principle of convection. The heating element is not located within the specimen chamber of the oven, but in a separate section of the oven.

- What is the difference between Oven and Incubator?

A laboratory oven and a laboratory incubator are both commonly used in laboratory settings, but they have different purposes and functions.

A laboratory oven is used for drying, heating, or sterilising materials and is typically designed to operate at higher temperatures than a laboratory incubator. A laboratory oven typically uses air convection to circulate hot air throughout the chamber, and can be set to a specific temperature or temperature range. Ovens generally control temperatures +80°C and up.

A laboratory incubator, on the other hand, is used for maintaining a controlled, temperature-regulated environment for cell cultures, microbiological specimens, or other biological materials. Unlike a laboratory oven, a laboratory incubator is designed to maintain a temperature close to the physiological temperature of the material being incubated, usually between 30°C and 40°C. A laboratory incubator can also provide additional functions, such as humidity control and CO2 control, which are essential for the growth and maintenance of many types of cells and biological specimens.