Natural Convection Ovens TO

For research, development, testing and quality control you need an efficient and consistent laboratory oven. These models feature natural heat convection, with no fan air circulation, providing gentle heat within the oven chamber.

Australian Made by Thermoline, our ovens are reliable and long-lasting perfect for all laboratory and industrial functions.

Overview

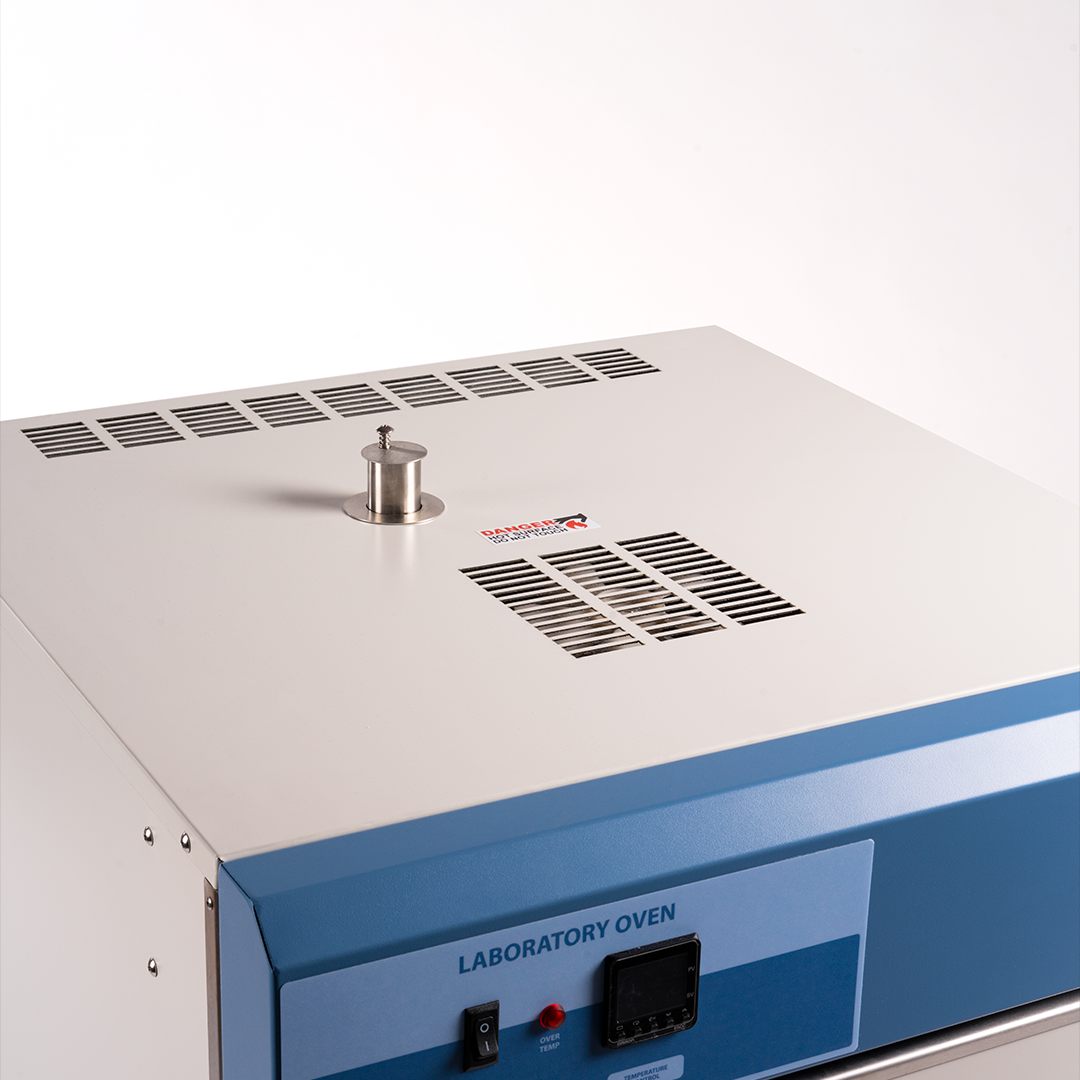

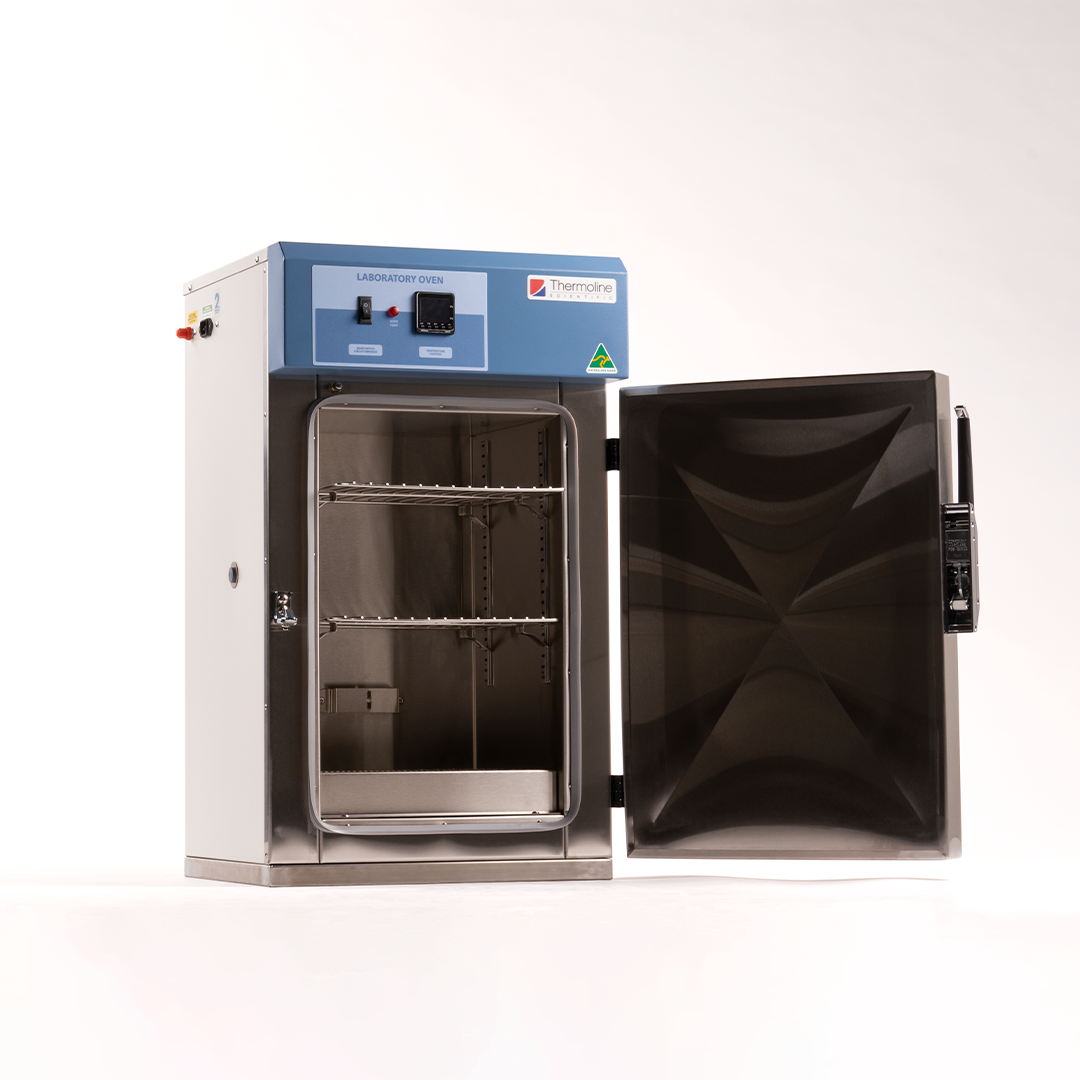

The natural convection laboratory ovens, manufactured by Thermoline, operate through the natural convection process, which relies on the movement of air caused by the difference in density between the heated and unheated air. The chamber is made of 304 stainless steel and is insulated with 50mm fibreglass to minimise heat loss. Shelving is stainless steel and adjustable.

Key Features

- Natural Convection Process: Utilises the natural movement of air for heating, eliminating the need for a fan.

- 304 Stainless Steel Chamber: Provides durability and resistance to corrosion, ensuring long-term use.

- Insulated with 50mm Fibreglass: Reduces heat loss, enhancing energy efficiency.

Benefits

- Quiet Operation: Without the need for a fan to circulate the air, these ovens operate quietly, creating a more pleasant working environment.

- Cost-Effective: Natural convection ovens are less expensive to operate than forced convection ovens due to their simpler design and lack of a fan, leading to lower maintenance costs.

- Energy Efficiency: The thick fibreglass insulation minimises heat loss, making the ovens more energy-efficient and reducing operating costs.

Considerations

The natural convection process may result in slower heating rates and longer drying times compared to forced convection ovens, and the spatial temperature uniformity is not as consistent as that in fan-forced ovens. However, the advantage of a natural convection oven is its quiet and cost-effective operation.

Summary

Thermoline's natural convection laboratory ovens provide a reliable and efficient solution for various heating and drying applications. With their durable construction, quiet operation, and energy efficiency, these ovens are an excellent choice for laboratories looking to minimise costs and enhance their working environment. Trust Thermoline for all your laboratory oven needs and experience the benefits of our high-quality, Australian-made equipment.

Specifications

- Dimensions

-

TO-30G TO-150G External WxDxH (mm) 430x400x730 630x660x1010 Internal WxDxH (mm) 300x280x420 500x510x600 Clearance Front (mm) 430 630 Back (mm) 100 Sides (mm) 100 - Technical Specifications

-

TO-30G TO-150G Temperature Range Ambient +10°C to 200°C Temperature Uniformity +/-2°C @ 100°C +/-4°C @ 100°C Heater Power 500 watts 900 watts Electrical 2.5A/230V 4A/230V Nominal Capacity 30L 150L Porthole Diameter 13mm Weight 50kg 100kg - Features

-

TO-30G TO-150G Shelves (max @100mm spacing) 2 (max 3) 3 (max 4) Lockable Castors X ✔ False Floor covering heater ✔ ✔ Fibreglass Insulation ✔ ✔ Omron E5CC-T ✔ ✔ - Safety

-

TO-30G TO-150G Over Temperature Safety ✔ ✔ Over Current Protection ✔ ✔ - Options

-

TO-30G TO-150G BMS Plug No volt contact closure plug and socket connection to a Building Management System Additional Shelves Additional Stainless Steel shelves to suit Door Locks Key lockable door locks

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is the difference between a lab oven and a drying oven?

- A drying oven is design to remove moisture from the oven chamber by introducing dry air into the chamber. These ovens are typically designed to provide a consistent and low humidity environment, which is important for drying materials effectively. Drying ovens often feature a vent or exhaust system that allows moisture to be removed from the oven workspace. Generally speaking, a regular lab oven does not exhaust air so the moist air may continue to circulate inside the chamber.

- Can I use a lab oven as a glassware drying oven?

- You can, however, as the moist air from the wet samples would be recirculated within the chamber, the drying rate is reduced and in many cases, will not properly dry.

- What is the process difference between a lab oven and a drying oven?

- A drying oven is designed to remove moisture from the oven chamber by introducing dry air. A lab oven's sole purpose is to designed to heat samples only. It works by recirculating the air around the chamber over a heating element that is controlled by a temperature controller.

- How do Laboratory Ovens Work?

- A laboratory oven works via the principle of convection. The heating element is not located within the specimen chamber of the oven, but in a separate section of the oven.

- What is the difference between Oven and Incubator?

A laboratory oven and a laboratory incubator are both commonly used in laboratory settings, but they have different purposes and functions.

A laboratory oven is used for drying, heating, or sterilising materials and is typically designed to operate at higher temperatures than a laboratory incubator. A laboratory oven typically uses air convection to circulate hot air throughout the chamber, and can be set to a specific temperature or temperature range. Ovens generally control temperatures +80°C and up.

A laboratory incubator, on the other hand, is used for maintaining a controlled, temperature-regulated environment for cell cultures, microbiological specimens, or other biological materials. Unlike a laboratory oven, a laboratory incubator is designed to maintain a temperature close to the physiological temperature of the material being incubated, usually between 30°C and 40°C. A laboratory incubator can also provide additional functions, such as humidity control and CO2 control, which are essential for the growth and maintenance of many types of cells and biological specimens.

- Can a laboratory oven be used as an incubator?

- An oven cannot be used as a lab incubator because most ovens cannot maintain the low temperatures required for incubation purposes.