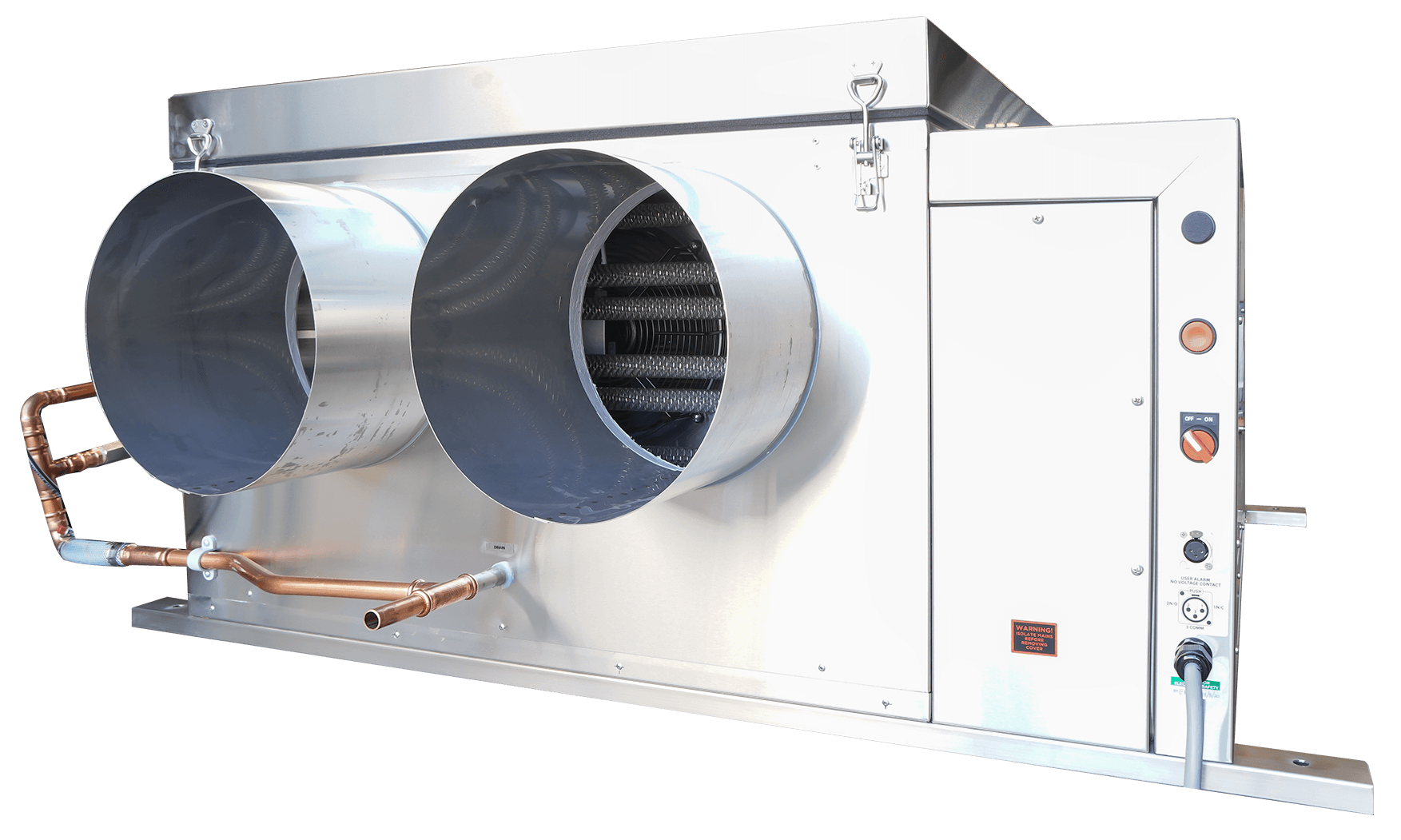

Room Conditioning Units TCU

The TCU plug in systems are ideal where large capacity temperature and humidity control is required. You simply start with the room, and we can provide the temperature and humidity control solutions.

Custom made ducting is available to suit and advice on room type and construction is available by our expert engineering team. Thermoline can project manage the entire built and install offering you a complete turn-key solution.

Overview

Thanks to our STAR X touchpad control system, you can easily adjust and program the temperature and humidity settings in coolrooms. Connection via ethernet allows the operator to check performance conditions quickly via a live trend screen or download logged data to a USB for viewing in an Excel spreadsheet.

Key Features

- Robust Refrigeration Systems: Ensures fast recovery times after door openings to reduce condition fluctuations.

- Uniform Airflow: Heavy-duty axial fans distribute air evenly, preventing 'short cycling' and maintaining consistent conditions.

- Advanced Temperature Control: Coil-sheathed, electric resistance elements with localised over-temperature protection for additional safety.

Benefits

- Precise Environmental Control: Ideal for controlled material testing, shelf-life testing, and climate tests on various materials.

- Consistent Conditions: Uniform airflow and quick recovery times ensure stable conditions in coolrooms.

- Comprehensive Monitoring: The STAR X system provides real-time monitoring and easy data logging, enhancing operational efficiency.

Industries Benefiting from Thermoline Coolroom Units

- Pharmaceutical

- Biomedical

- Biotech

- Food Industry

- Concrete Shrinkage Testing

- Medical Apparatus

- Plastics/Injection Mould

- Chemicals

- Healthcare

- Electronics

Humidification and Airflow

- Humidification: Generated by an atmospheric pressure steam generator, activated by a pulsed signal from the humidity controller.

- Airflow System: Prevents air 'short cycling' and minimises spatial non-uniformity.

Thermoline environmental control units are designed to fit coolrooms, providing precise, reliable, and efficient temperature and humidity control for various industries. Ensure your coolroom conditions are optimal with Thermoline’s advanced technology.

Specifications

- Technical Specification

-

TCU-4 TCU-5 Panel Cut Out Size 905x905mm 4x 300mm dia holes

(2x Outlet/2x Return)

Temperature Range +5°C to +50°C Temperature Uniformity +/- 2.0°C (Load Dependant) Humidity Range 30% to 90% Humidity Uniformity +/- 5% (Load Dependant) Heating Element Power 1500 watts 3x 1000 watts Electrical 15A/230V 20A/415V/3Ph Recommended Room Size 20-30m3 Recommended Internal Room Height 2300mm + (Plug is 250mm from ceiling) Recommended Coolroom Panel 100mm Fire Rated PIR Panel Weight 190kgs 220kgs Refrigerant Type R507 - Features

-

TCU-4 TCU-5 STAR X Touch Screen ✔ ✔ Ethernet Port ✔ ✔ Download data to USB ✔ ✔ Battery Backed-up Alarms ✔ ✔ BMS ✔ ✔ Supply Line Water Filters 1x Carbon, 1x Sediment 1x Carbon, 1x Sediment Fibreglass Insulation ✔ ✔ - Safety

-

TCU-4 TCU-5 Over Current Protection ✔ ✔ Over Temperature Safety ✔ ✔ Element Safety Cut Out ✔ ✔ - Options

-

TCU-4 TCU-5 Ducting Stainless steel ducting can be manufactured to suit your room CO2 Control Set Point Control of CO2 Between Ambient and 3000ppm

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What panel should the coolroom be constructed from?

- The cool room must to be constructed from 100mm PIR Panel or a 100mm panel with the same Thermal Resistance as PIR or better than 0.020watts/M2/Kelvin.

- What is the cutout size for the TCU-4 ceiling mounted unit?

- The unit will fit into a 905mm x 905mm hole in the roof. A clearance above the roof of 800mm is needed for the Conditioning unit. However, 1000mm is preferred for access to servicing.

- What should be the internal height of the room?

- Internal height of the room will need to be at least 2300mm, as the conditioning plug will take up 250mm of roof height.