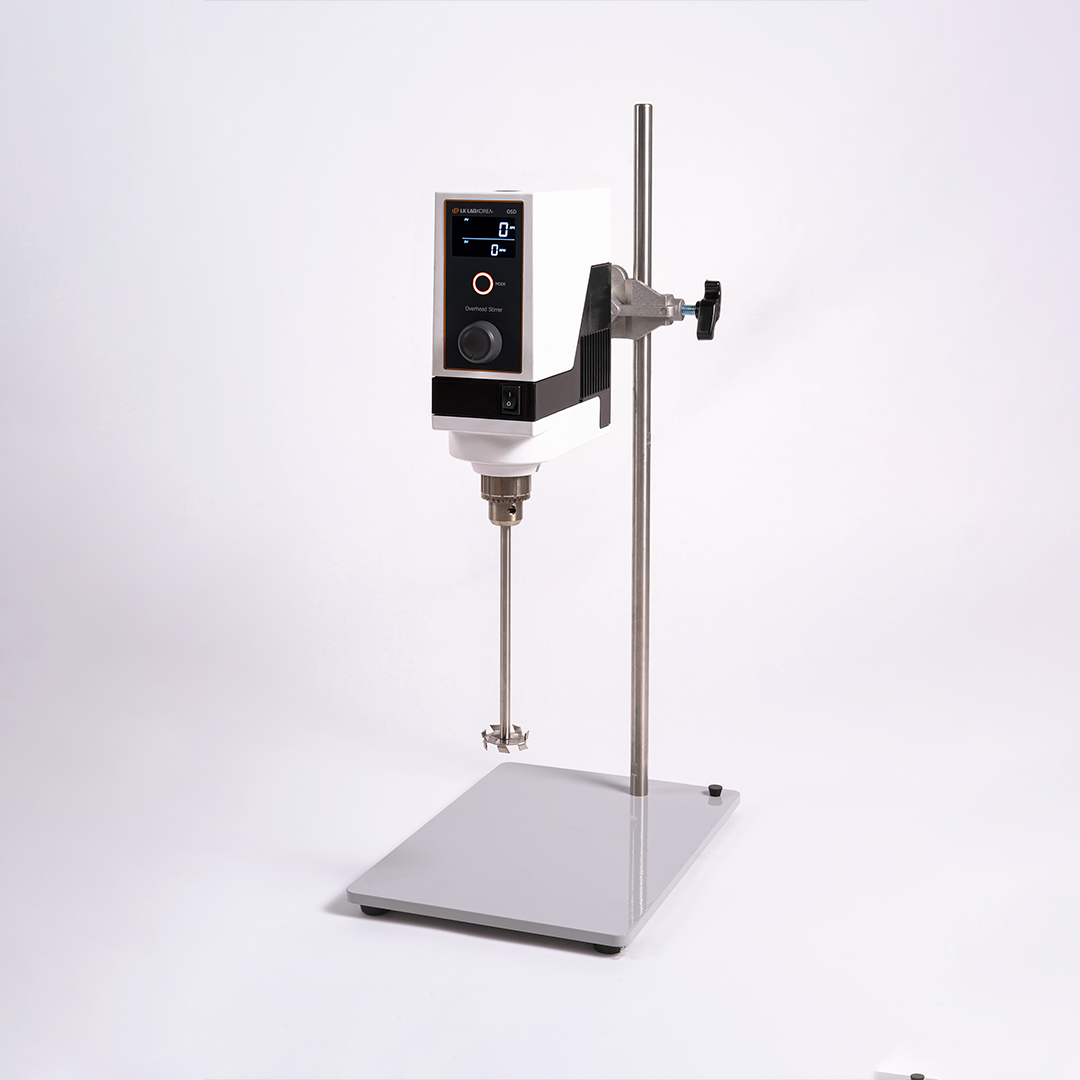

Digital Overhead Stirrer OSD

These overhead stirrers are powerful, economic and easy to operate. They offer a steady and constant stirring speed via a digital control.

All models supplied with powerful DC motors which are quiet and require no maintenance. Various stirring shafts are available.

Overview

This overhead stirrer is perfect for applications that require smooth and consistent stirring. The model boasts a Digital Feedback Controller, providing precise RPM control, an easy-to-use jog dial switch for RPM adjustments, and a backlit LCD screen with excellent visibility.

Key Features

- Precise RPM Control: The Digital Feedback Controller ensures accurate RPM settings for consistent stirring.

- User-Friendly Design: Features an easy-to-use jog dial switch and a backlit LCD screen for excellent visibility.

- Effortless Shaft Switching: The screw shaft chuck allows for easy switching between stirring shafts.

Additional Features

- Slow Start/Stop Function: Prevents sample splashing, ensuring clean and efficient stirring.

- Durable Construction: Chromium coating provides rust-free long-term use.

- Adjustable Impeller Height: Allows for flexible and customised stirring setups.

- Space-Efficient Design: Slim and compact, ensuring high space efficiency.

- Safety Features: Motor overheating prevention feature and overload protection ensure safe operation.

Product Components

- Main stirrer

- Support base with rod and clamp (Plate base 200 x 315 and rod 800mm)

- Propeller stirring shaft (propeller or diamond type)

Specifications

- Model: OSD-10

- Capacity: 25 litres of water

- Viscosity Handling: Up to 70,000 mPas

- Maximum Torque: 200 Ncm

- Speed Range: 100 to 2000 rpm

- Material: ABS and aluminium

- Maximum Impeller Shaft Diameter: 10mm

- Display: Digital LCD with backlight

- Timer Function: Allows for a maximum of 99 hours and 59 minutes of stirring

- Protection Features: Overload and heat protection for the motor

Benefits

- Enhanced Precision: The Digital Feedback Controller and precise RPM adjustments ensure consistent and accurate stirring for various applications.

- Durable and Safe: Chromium coating and motor protection features provide long-term durability and safe operation.

- User-Friendly and Efficient: The easy-to-use jog dial, backlit LCD, and compact design ensure a user-friendly experience and high space efficiency in any laboratory setting.

Choose this advanced overhead stirrer for reliable and precise mixing, ensuring your laboratory applications run smoothly and efficiently.

Technical Data

-

BrandLK Lab

-

Capacity25L (water)

-

Electrical0.5A/230V

-

Speed Range100 - 2000rpm

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is the difference between an overhead stirrer and homogenizer?

The main difference between a stirrer and a homogenizer is their purpose and operating mechanism. Stirrers are used to mix liquids, while homogenizers disrupt and homogenize biological samples. Stirrers typically use a rotating blade to create a vortex that stirs the liquid, while homogenizers use mechanical force to break down cell membranes and create a uniform mixture of the sample.

- What is an overhead stirrer?

A laboratory overhead stirrer is a motorised instrument used to mix and stir large volumes of liquid samples in laboratory settings. It consists of a unit mounted on a stand or a laboratory bench, and a stirring rod or impeller attached to the motor unit.

The motor unit of an overhead stirrer typically has variable speed controls, which allow the user to adjust the speed and torque of the stirring rod or impeller. Depending on the sample being stirred, the stirring rod or impeller can be made of different materials, such as stainless steel or PTFE.

Overhead stirrers are commonly used in chemistry, biology, and other scientific fields that require mixing large volumes of liquid samples. They are particularly useful in applications with a high degree of homogeneity, such as in preparing emulsions, suspensions, and solutions. They can also be used in applications requiring precise control of the stirring process, such as in mixing highly viscous materials or in processes requiring a specific mixing speed or duration.

- What is an overhead stirrer used for?

An overhead stirrer is a laboratory device used to mix or stir liquids, suspensions, and viscous materials. It is typically used in scientific research, chemical analysis, and industrial production processes where thorough mixing and uniformity are required.

The overhead stirrer is designed with a motor-driven shaft that rotates an impeller or mixing blade suspended above the liquid being mixed. The stirring blade can be customised to suit the particular application and can be made of various materials including stainless steel, plastic, and PTFE (polytetrafluoroethylene) for use with corrosive or aggressive substances.