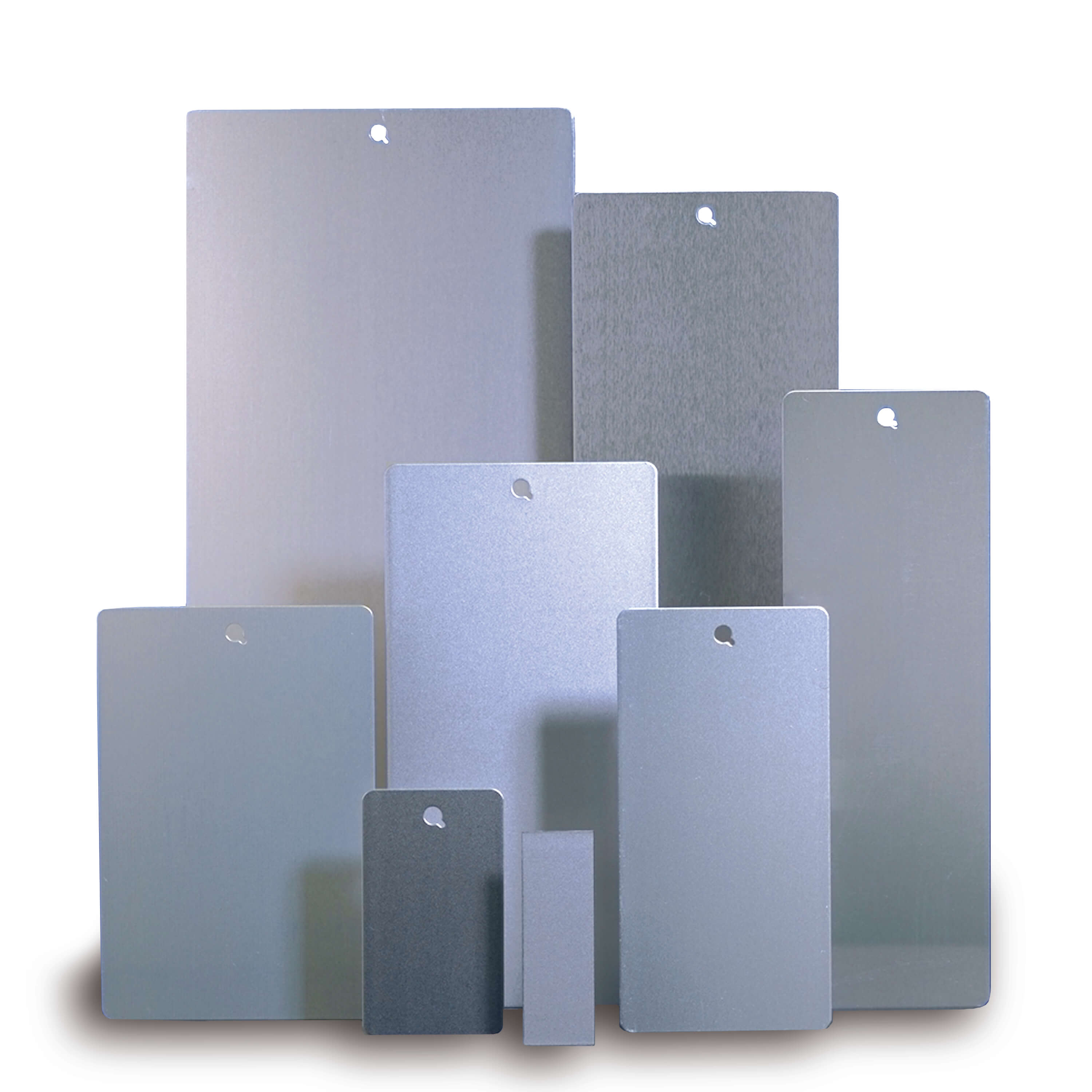

Standard Test Panels Q-PANEL

Thousands of labs around the world use millions of steel and aluminium test Q-Panels every year for colour development, weathering exposures, salt spray and corrosion testing, physical properties testing and quality control.

Look for the Q-shaped hole. It's our trademark and your assurance of quality.

Overview

If coatings tests are to be reliable and reproducible, they must be performed on a substrate that is reasonably consistent from test to test. Unfortunately, ordinary commercial sheet steel displays wide variations in surface properties, which affect the bonding of coatings.

Sources of Variability

Surface problems can come from a number of sources:

- Surface texture varies with the condition of the rollers used by the steel mill to cold roll the steel to its final thickness.

- Surface cleanliness varies with the mill's cleaning procedure, especially the procedures used to control carbon smut. Carbon smut is often baked onto the steel during the high-temperature annealing process, which follows rolling. This carbon smut is impossible to remove except by mechanical abrasion.

- Rust varies with the care taken in handling (a) at the steel mill, (b) during transport and storage, and (c) during fabrication.

- Steel stored for a long time with rust-inhibiting oil will react to form an incomplete oxide known as oil stain.

The result is that ordinary steel is unsuitable for many coatings tests. Although some commercial steel provides an excellent surface for coatings, you are just as likely to find steel that gives poor adhesion and rust resistance even with suitable coatings. A single mill will often produce excellent and very inferior surface quality, depending upon several uncontrolled factors. Cleaning and phosphating help, but they cannot overcome surface defects formed at the mill. Q-Panel steel and aluminium test substrates from Q-Lab minimise metal variability as a source of bias in critical paint, coating and adhesion tests. They are clean, consistent, convenient, and economical.

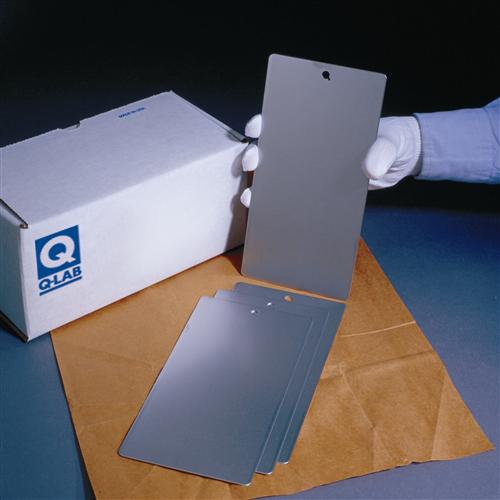

Clean

The Q-Panel production process thoroughly cleans panels and removes any oil from the surface. Special handling assures that all panels are completely clean when they are packaged. Steel panels are packed in plastic bags in quantities of 20 to 50 panels (depending on type and thickness), with a vapour phase rust inhibitor inside a sturdy cardboard carton, for a shelf life of several years. Aluminium panels are packed similarly, except without the rust inhibitor.

Consistent

Three factors ensure Q-Panel substrates are consistent, high quality and low cost:

- volume metal purchasing from selected mills

- automated production on a high-speed line

- rigorous inspection at several processing stages

Convenient

Panels are supplied pre-cleaned, with a 6mm (ź) Q-shaped hole (it's our trademark and your assurance of quality). The panels have rounded corners and deburred edges for safety and ease of handling. Our inventory of over a million paint test panels means that 95% of our orders are shipped from stock. In most cases, panels can be used right out of the box.

Economical

Because of high volume production, Q-Panel substrates cost less than you might expect for a standardised surface. Purchasing clean, safe, standardised panels reduces the time lab personnel must spend cleaning and handling panels.

Specifications

- Dimensions - Steel Panels

-

TYPE DESCRIPTION QD CRS SAE 1008/1010; 0.020" thick (0.5 mm); smooth finish R CRS SAE 1008/1010; 0.032" thick (0.8 mm); dull finish S CRS SAE 1008/1010; 0.032" thick (0.8 mm); ground finish D CRS SAE 1008/1010; 0.010" thick (0.25 mm); smooth finish DT CRS SAE 1008/1010; 0.010" thick (0.25 mm); bright tinplate RS CRS SAE 1008/1010; 0.063" thick (1.5 mm); ground finish - Dimensions - Aluminium Panels

-

TYPE DESCRIPTION A Alloy 3003H14; 0.025" thick (0.6 mm); bare mill finish AL Alloy 3003H14; 0.025" thick (0.6 mm); chromate finish AR Alloy 2024T3; 0.063" thick (1.5 mm); bare mill finish AD Alloy 2024T3 Alclad; 0.063" thick (1.5 mm); alclad finish

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- Can Q-Lab produce custom panels?

- Yes. Custom panels can be ordered in a range of shapes, sizes, alloys and finishes including curved, sand-blasted, perforated and pre-painted.

- Why are Q-Panel the world standard in testing substates?

- If coatings tests are to be reliable and reproducible, they must be performed on a substrate that is reasonably consistent from test to test. Unfortunately, ordinary commercial sheet steel displays wide variations in surface properties, which affect the bonding of coatings. Q-PANEL steel and aluminium test substrates from Q-Lab minimise metal variability as a source of bias in critical paint, coating and adhesion tests. They are clean, consistent, convenient, and economical.

- Can Q-Panels be used to standardise corrosion loss?

- Q-Lab can also supply a range of corrosion test coupons. Corrosion test coupons ensure repeatability and reproducibility when performing laboratory corrosion testing. They help a user independently monitor the test conditions in a corrosion chamber by measuring the mass loss of the coupons as the test progresses. CX corrosion coupons are designed to meet the stringent requirements specified in modern corrosion test methods.

- How does Q-Lab prevent the steel panels from rusting during transit and storage?

- The Q-Panel production process thoroughly cleans panels and removes any oil from the surface. Special handling assures that all panels are completely clean when they are packaged. Steel panels are packed in plastic bags in quantities of 20 to 50 panels (depending on type and thickness), with a vapour phase rust inhibitor inside a sturdy cardboard carton, for a shelf life of several years. Aluminium panels are packed similarly, except without the rust inhibitor.