QCT Condensation Tester QCT

- ASTM D4585, Testing Moisture Resistance of Coatings with Controlled Condensation

- ISO 6270-1, Paints and Varnishes - Humidity (Continuous Condensation)

- BS 3900, Part F9, Determination of Resistance to Humidity (Continuous Condensation)

Overview

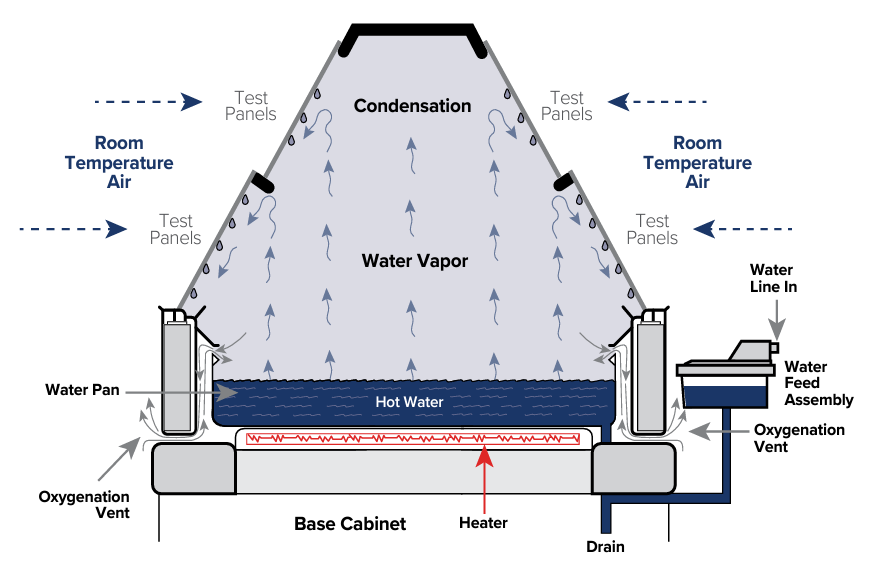

The QCT Condensation Tester is an advanced tool designed to simulate and accelerate damage caused by dew on metals, paints, and organic materials using 100% condensing humidity. Increasing moisture temperature speeds up natural exposure processes, providing valuable insights into material durability and performance.

Key Features and Benefits

-

Advanced Humidity Control:

- The QCT test chamber generates 100% relative humidity by heating water in the chamber's bottom, producing hot vapor. Test panels form the chamber's walls and are cooled on their reverse side by laboratory air, causing condensation on the front side of the specimens.

- The QCT test chamber generates 100% relative humidity by heating water in the chamber's bottom, producing hot vapor. Test panels form the chamber's walls and are cooled on their reverse side by laboratory air, causing condensation on the front side of the specimens.

-

Dynamic Testing Cycles:

- The tester's innovative design uses room air cooling to create a temperature differential across the specimen thickness, essential for condensation. It supports cyclic testing, alternating between wet and dry phases to simulate real-world conditions.

- The tester's innovative design uses room air cooling to create a temperature differential across the specimen thickness, essential for condensation. It supports cyclic testing, alternating between wet and dry phases to simulate real-world conditions.

-

Corrosion-Resistant Construction:

- The QCT tester is durable and reliable. It is made with anodized aluminium and a glass-lined water pan featuring a magnesium anode for cathodic protection. It holds up to 62 panels (75mm x 150mm) or 48 panels (100mm x 150mm).

- The QCT tester is durable and reliable. It is made with anodized aluminium and a glass-lined water pan featuring a magnesium anode for cathodic protection. It holds up to 62 panels (75mm x 150mm) or 48 panels (100mm x 150mm).

-

Efficient Water Usage:

- The tester uses ordinary tap water, which becomes pure distilled water through the evaporation and condensation process. It has an automatic water feed system and consumes approximately 2 litres per day.

- The tester uses ordinary tap water, which becomes pure distilled water through the evaporation and condensation process. It has an automatic water feed system and consumes approximately 2 litres per day.

-

Versatile Testing Capabilities:

- Screening paints for blister resistance at 55°C over a weekend.

- Evaluating oil-based rust inhibitors in less than 120 hours at 38°C.

- Rating mill-applied oils in just a day.

- Testing surface reactivity of cold-rolled and galvanized steel in hours.

- Assessing wood finishes for blistering, moisture, and mould resistance.

Ease of Use

- Simple Installation and Operation:

- The QCT tester is easy to use and install. Simply plug it in, add water, and start testing. The unit can be placed in your office, lab, or factory, as it produces heat and water vapour similar to an additional person in the room.

- The QCT tester is easy to use and install. Simply plug it in, add water, and start testing. The unit can be placed in your office, lab, or factory, as it produces heat and water vapour similar to an additional person in the room.

- Convenient Panel Inspection:

- Test panels can be inspected frequently without altering test conditions by removing the panel and placing a blank in its spot.

Additional Capabilities

- Freeze/Thaw Cycles:

- Wet panels can be manually removed from the QCT tester, frozen, and then reinserted. This feature accelerates some failure modes, providing a comprehensive testing solution.

The QCT Condensation Tester offers fast, reliable, and versatile testing for various materials, making it an essential tool for any laboratory focused on material durability and performance evaluation. Its advanced features, efficient water usage, and ease of use ensure that it meets the demanding requirements of modern testing environments. Choose the QCT Condensation Tester for comprehensive and accelerated material testing.

Specifications

- Dimensions

-

QCT External WxDxH (mm) 1370 × 530 × 1350 Internal WxDxH (mm)

max, bottom1200 × 480 × 250 WxDxH (mm)

min, top1200 × 150 × 250 - Technical Specifications

-

QCT Specimen Capacity 62 Panels, 75 × 150 mm (3 × 6 in)

or 48 panels, 100 × 150 mmWeight Capacity 45 kg (100 lbs) evenly distributed when using the Humidity Enclosure Weight Equipment weight - 80 kg (175 lbs)

Shipping weight - 125 kg (275 lbs)Temperature RT up to 72 °C Heater 1500 W Thermostat Adjustable from 27-72 °C Construction Corrosion-resistant anodised aluminum Water Pan Stainless Steel Electrical 120 V ± 10%, 1-Phase, 60 Hz, 14 A

-or 230 V ± 10%, 1-Phase, 50 Hz, 7 A

-or 230 V ± 10%, 1-Phase, 60 Hz, 7 A

Transformer kits available for 100 V or 200 V operationWater System Automatic water feed connects to ¼ in (6 mm) plastic tubing Water Consumption ~2L/day Lab Recommendations Temperature (°C 23 ± 5 °C Relative Humidity (%) 50 ± 25% - Features

-

QCT Full-color Touchscreen Display ✔ USB Port ✔ Multi-color LED Light ✔ Standard Caster Wheels ✔

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is a condensation tester?

- The QCT condensation tester simulates the damaging effects of outdoor moisture attack by condensing warm water directly onto test specimens. In a few days or weeks, the QCT tester can reproduce the damage due to moisture that occurs over months or years outdoors.

- How does the QCT condensation tester work?

- It uses 100% condensing humidity to simulate and accelerate damage caused by rain and dew on metals, paints, and organic materials. It accelerates over natural exposures by increasing moisture temperature. The QCT tester replaces water immersion and ordinary (non-condensing) humidity tests.

- What are some of the Standards does the QCT conform to?

- The QCT tester conforms with several standards, including: ASTM D4585, Testing Moisture Resistance of Coatings with Controlled Condensation ISO 6270-1, Paints and Varnishes - Humidity (Continuous Condensation) BS 3900, Part F9, Determination of Resistance to Humidity (Continuous Condensation)

- Where is the QCT tester manufactured?

- Along with the entire Q-Lab range, the QCT tester is manufactured in Ohio, USA.