Cytotoxic Drug Safety Cabinets CGA

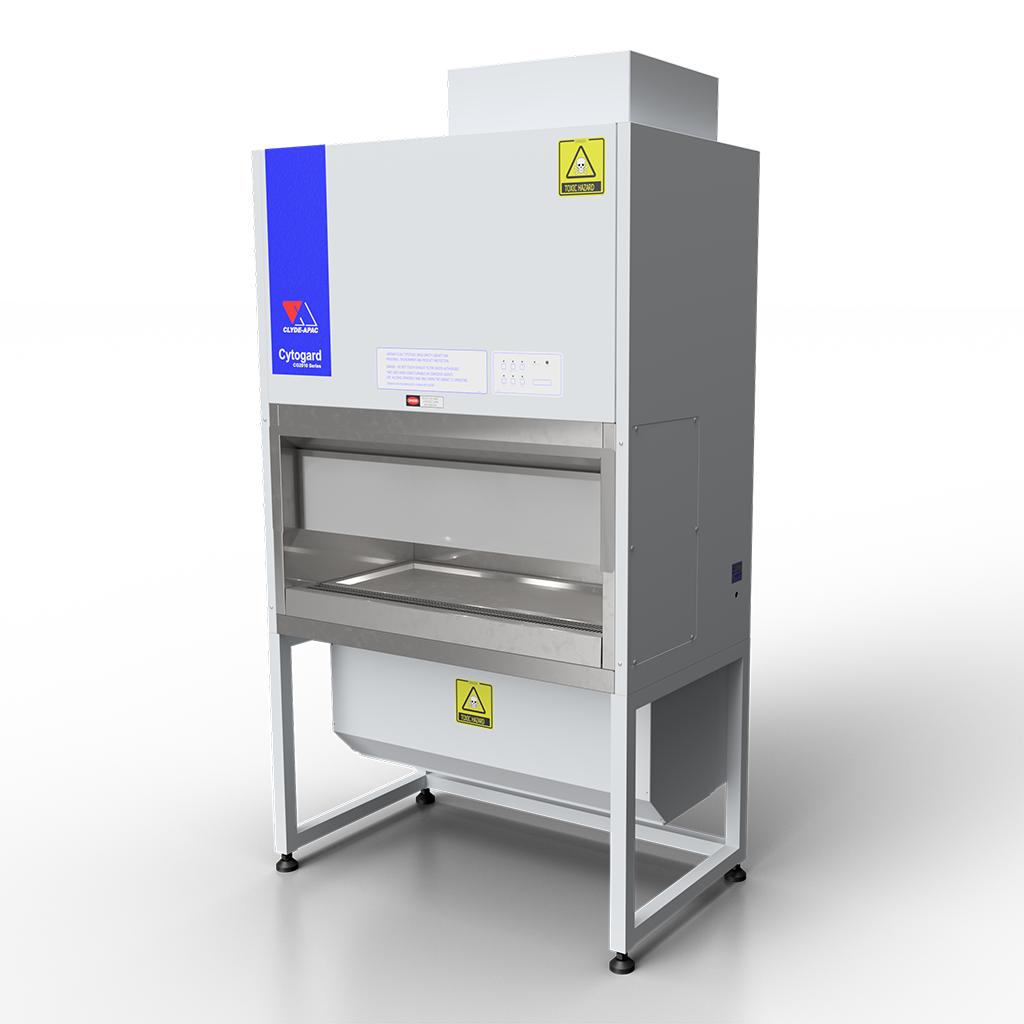

The Australian Made Cytogard Cytotoxic Drug Safety Cabinets are part-recirculating laminar air flow enclosures with high efficiency particulate air (HEPA) filtration of exhaust air and an air barrier at the work opening.

The HEPA-filtered vertical laminar air flow is recirculated in the work zone and creates an ultra-clean work environment for product protection. An air barrier between the operator and the work zone is maintained by a flow of room air into a full-width grille in the work opening.

Overview

The barrier air mixes with the recirculated laminar flow air in a sump underneath the work surface and is exhausted from the cabinet via a HEPA filter which is located directly under the work tray. All positive pressure zones and filter seals are surrounded by negative pressure zones so as to contain potentially hazardous aerosols.

Cytogard Cytotoxic Drug Safety Cabinets are produced with a work zone width of 90cm, 120cm or 180cm and are free-standing units that incorporate a floor stand. The standard cabinets have an exhaust discharge on the right-hand side with optional left-hand side or top exhaust available. Top exhaust is typically specified where cabinet exhaust air is to be entrained into the room exhaust.

These cabinets provide advanced system-monitoring technology and a number of unique design features intended to enhance safety and ease of use.

Cytotoxic Drug Safety Cabinet (CDSC) Provides the following protections:

- Protection of cabinet users and other staff from exposure to aerosols or vapours which may be generated in the preparation, manipulation and dispensing of cytotoxic drugs.

- Protection of drug products so that they may be prepared in an environment that is essentially free from particulate and biological contamination.

- Protection of cabinet maintenance personnel from the residue of drug particles that can contaminate filters, fans and other mechanical components.

The need for a new cabinet design led to the publication in 1982 of AS2567, the world's first standard for cytotoxic drug safety cabinets. AS 2639, first published in 1983, deals with cabinet use and installation, including the location of the cabinet in a special cleanroom. Revised versions of these documents were published in 1994. These Cytogard Cytotoxic Drug Safety Cabinets are designed and manufactured to comply with AS2252.5, an Australian Standard that has undergone a significant revision in 2017. The new standard is the most comprehensive revision of the CDSC standard and improves the overall protection of the operator, facility and environment.

Each cabinet is factory-certified to meet the specified performance requirements. These cabinets may also be used where the handling of other drugs and chemicals requires both containment and aseptic manipulation.

Technical Data

-

BrandAES Environmental

-

Models AvailableThree

-

Sizes900mm/1200mm/1800mm

-

Electrical2A/230V

-

Filter TypeHEPA

-

Complies WithAS 2252.5

Support

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is a Cytotoxic Drug Safety Cabinet used for?

A Cytotoxic Drug Safety Cabinet, also known as a Cytotoxic Hood, is a type of laboratory equipment designed specifically for handling and storing cytotoxic drugs, which are toxic to cells.

A Cytotoxic Drug Safety Cabinet, also known as a Cytotoxic Hood, is a specialised piece of equipment designed to provide a sterile and safe environment for handling hazardous biological and chemical materials, including cytotoxic drugs. Cytotoxic drugs have toxic effects on cells, often used in chemotherapy to destroy cancer cells. Cytotoxic drugs are known to be highly potent, carcinogenic, and mutagenic.

The cabinet protects workers and the environment from exposure to hazardous drugs and other dangerous substances. It draws in contaminated air from the work area, filters it through a HEPA (high-efficiency particulate air) filter, and then releases the clean air back into the room. The cabinet also creates a physical barrier between the worker and the hazardous material being handled, preventing direct contact and potential contamination.

Cytotoxic Drug Safety Cabinets are commonly used in pharmaceutical manufacturing, research laboratories, and hospitals where chemotherapy drugs are prepared and administered. These cabinets are essential in ensuring the safety of workers' and patients' safety and preventing contamination of the environment.

- What Australian Standards do I need to know for Cytotoxic Drug Safety Cabinets?

- The need for a new cabinet design led to the publication in 1982 of AS2567, the world’s first standard for cytotoxic drug safety cabinets. AS 2639, first published in 1983, deals with cabinet use and installation, including the location of the cabinet in a special cleanroom. Revised versions of these documents were published in 1994.

- What is the purpose of a Cytotoxic Drug Safety Cabinet?

- The primary purpose of a Cytotoxic Drug Safety Cabinet is to provide a controlled environment for handling these drugs, which can be harmful if they come into contact with skin or are inhaled. A Cytotoxic Drug Safety Cabinet uses a combination of physical and airflow barriers to prevent the release of cytotoxic drugs into the environment and to protect the user from exposure.

- Can Thermoline arrange installation and commissioning of my cabinet?

- Yes. Our suppliers have service divisions in most Australian states and territories and relies on qualified partners for other geographical locations. Each team is capable of providing on-site installation and NATA certification.