Standard Test Substrates

Showing 1-2 of 2 results

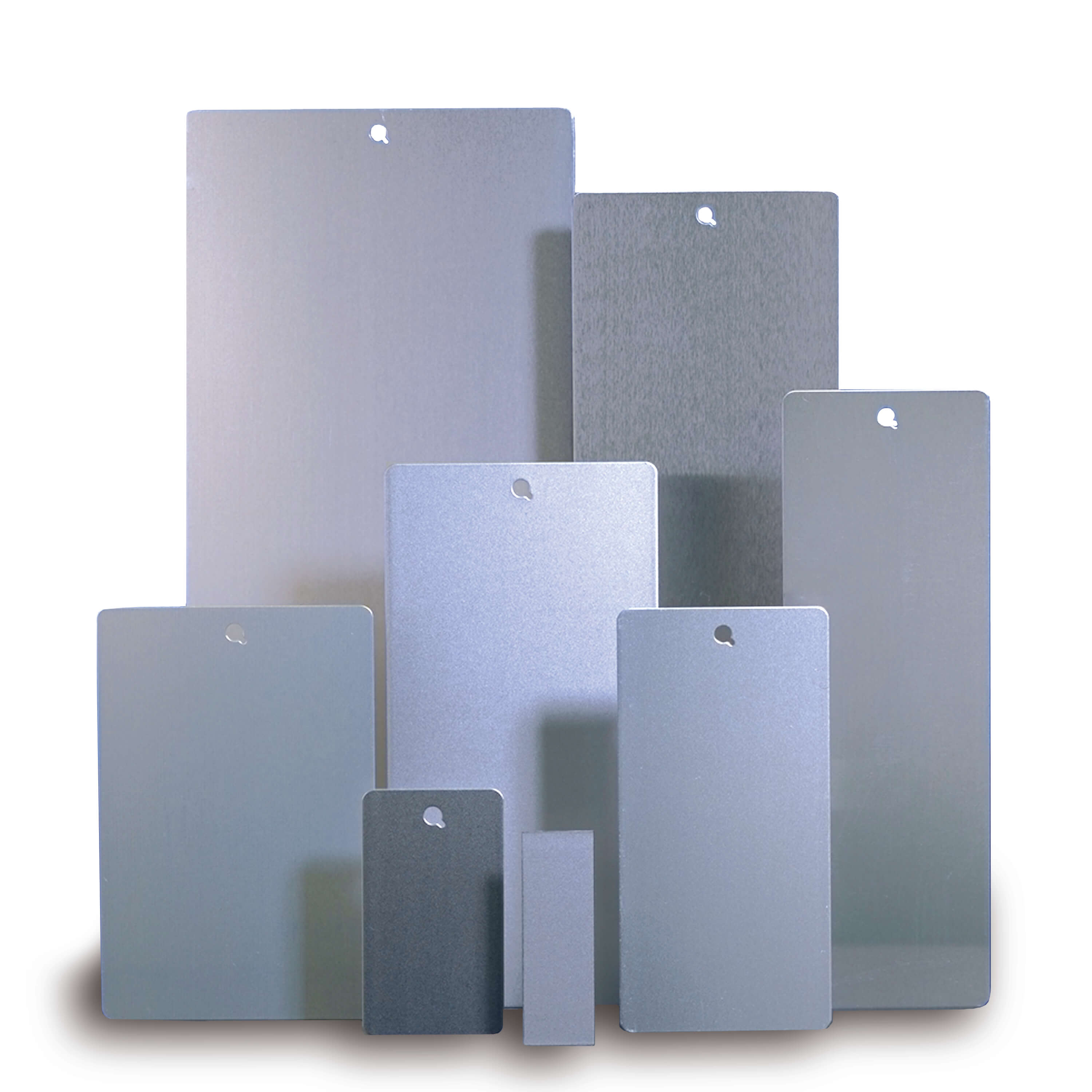

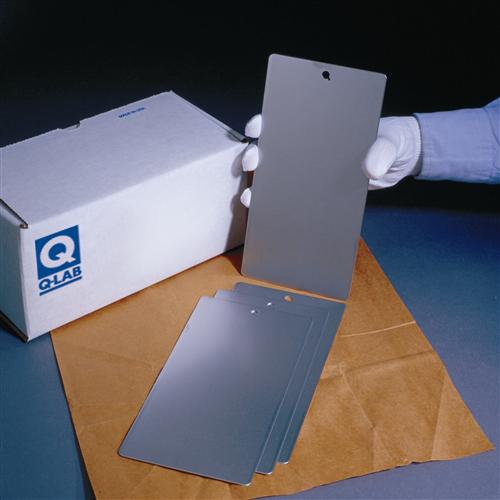

Standard Test Substrates

Q-PANEL

Q-Panel standard test substrates from Q-Lab are available in various sizes and finishes, fabricated from steel and aluminium.

These test panels are the world standard for a consistent and uniform test surface for paints, plating, adhesives, sealants, rust inhibitors and other coatings.

Specifications

- Brand: Q-Lab

Corrosion Test Coupons

CORROSION COUPONS

Corrosion test coupons help a user independently monitor the test conditions in the chamber, by measuring the mass loss of the coupons as the test progresses. This consistency and uniformity is now available through Q-Lab’s CX-series corrosion test coupons.

CX corrosion coupons are designed to meet the stringent requirements specified in modern corrosion test methods, such as GMW14872, GM9540P, SAE J2334, SAE J2721, ASTM B117, ISO 9227, and VDA-233-102.

Specifications

- Brand: Q-Lab